Understanding Different Pallet Types: A Deep Dive on Pallet Construction, Types of Pallets, and Uses

Understanding various pallet types is vital, as different types of pallets serve different purposes. Pallets are generally classified in four ways: by pallet material, construction, size and origin, and specialty purpose. Each type of pallet and material offers different advantages and disadvantages, pricing, and uses.

PalletTrader offers a variety of pallet types that can be used across industries. Partnering with PalletTrader gives you access to our online pallet marketplace and connects your team with our vast pallet supplier network so that you can find exactly what you need. We also offer procurement management, where we source pallets that match your specifications.

In this blog on pallet types, we take a deep dive into the different types of pallets available to help you make wise choices when purchasing pallets for your business. Read on to explore different pallet types and construction, their use cases, and how PalletTrader’s expertise can help transportation businesses like yours.

I: Pallet Type: Construction Style and Typical Uses

You’re likely aware that pallets can be constructed from wood, plastic, and other materials. What you may not know is that pallets also are classified by how they’re constructed. Here we compare and contrast different pallet types by construction and their typical usage.

Stringer vs. Block Pallets

Stringer pallets are constructed of parallel boards (stringers) running the length of the pallet. This type of pallet features two-way or partial four-way entry, if notched. Two-way entry means the pallet can only be loaded or unloaded on two sides. Four-way entry indicates that the pallet can be accessed along any of its four sides. Stringer pallets are the most economical option, which is why they are typically used to reduce costs and for standard shipping. Stringer pallets typically are used with lighter-weight products, for general warehousing, and when manual handling is likely.

In contrast, block pallets are constructed with blocks at the corners and center points of the pallet. Block pallets feature full four-way entry/access and cost 10 to 20 percent more than stringer pallets. They offer better weight distribution, easier handling, and greater durability. Block pallets are ideal for heavy loads, racking, and frequent handling. Block pallets often are used with heavy loads, in automated systems, and when handled at multiple points during transportation or storage.

Face Configurations

There are two types of face configurations for pallets: single and double faced. Single-faced pallets are constructed with a top deck (surface) but no bottom boards. Single-face pallets are best suited for one-way shipping and storage only (not for racking). These types of pallets on average cost 20 to 30 percent less than double-face pallets.

Double-face pallets are constructed with decks on the top and bottom. They are best for long-term use, racking, and frequent handling. If you choose a non-reversible double-face pallet, keep in mind that the top and bottom decks are of varying strength. Reversible double-face pallets, on the other hand, are constructed with identical tops and bottoms so that they are reversible.

Consider using PalletTrader+ managed services to offload pallet-related tasks to us. As a managed services customer, you receive expert advice from our team to help you choose the right pallet types for your business. We also offer procurement management, where we source pallets that match your specifications and provide ongoing quality assurance as part of our managed services.

II: Types of Pallets: Sizes and Regional Standards

Pallets also vary according to size and region. Here are some of the most common types of pallets by size and regional standards.

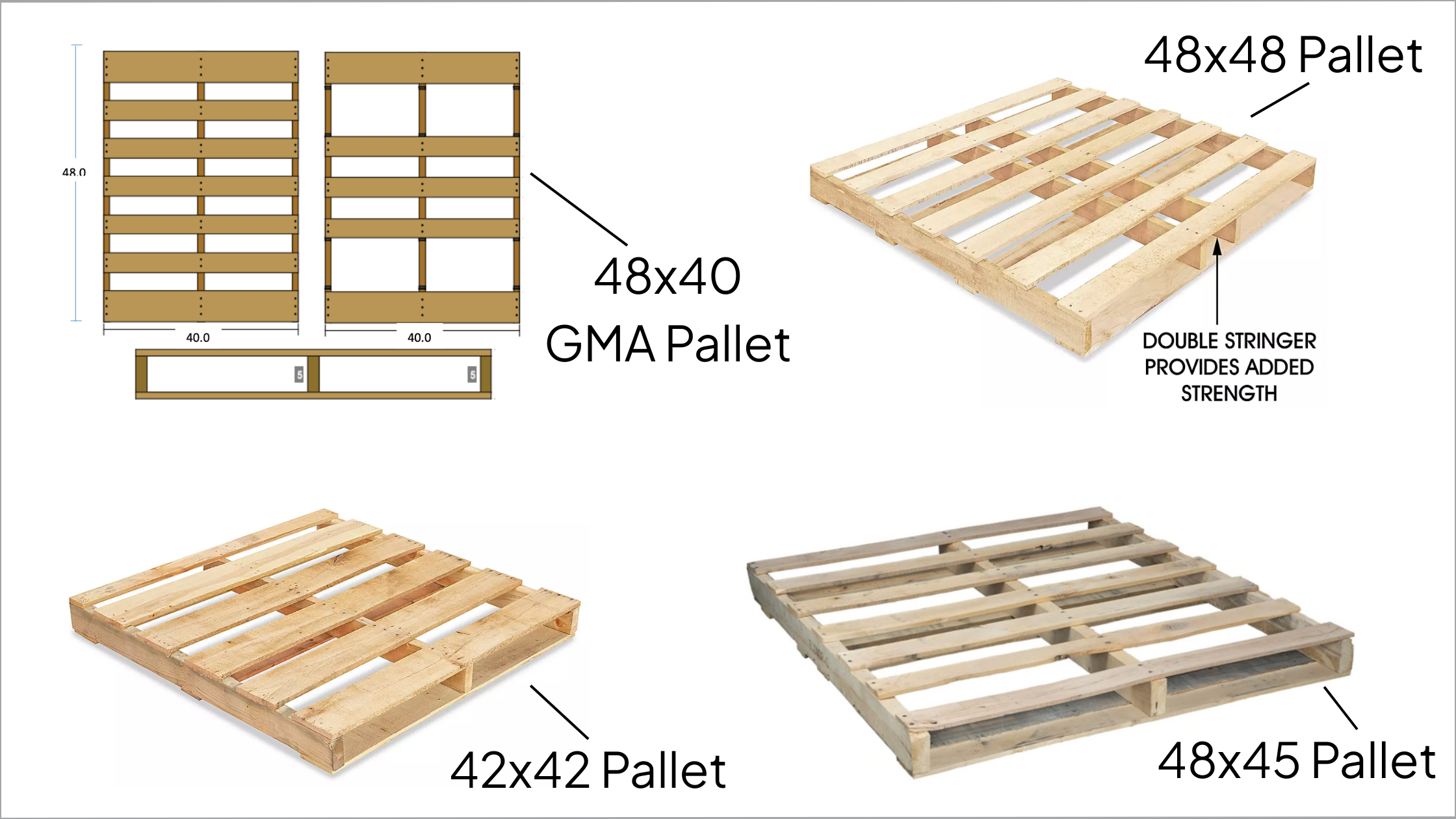

North American Standards

GMA (Grocery Manufacturers Association) pallets, which measure 48 inches by 40 inches, are the most common pallet size in North America. These pallets are often used for grocery, retail, and general distribution products. The typical weight capacity for GMA pallets is between 2,500 and 3,000 pounds. Twenty-four GMA pallets can be efficiently loaded onto a 53-foot trailer. Other common pallet sizes used in North America include: 48”x48” for drums, chemicals, and industrial products; 42”x42” for telecommunications and paint products; 48”x45” for automotive products; and 40”x48” for military and other specialty cargo.

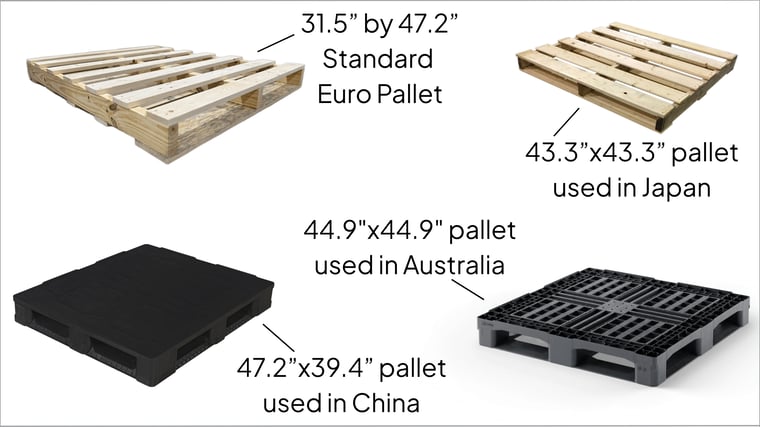

International Standards

European (EUR) pallets measure 31.5” by 47.2” and are the standard size used across Europe. They’re constructed of nine-blocks and must meet specific quality standards. European pallets are marked with a EUR or EPAL certification stamp. In Asia, there are three different pallet sizes that are most commonly used. These are: 43.3”x43.3”, used in Japan and South Korea; 47.2”x39.4”, used in China and Southeast Asia; and 44.9x44.9, the Australian standard pallet size. Other international sizes include ISO 1, the most common international size, and ISO 2 (EUR pallet). ISO standard sizes are designed for optimal container loading efficiency.

Looking to save time? Use PalletTrader’s online marketplace search and filter tool to filter by size, grade, geographic location, and certification. All of the suppliers participating in our marketplace are vetted to ensure their products meet quality standards. Transparent pricing allows you to compare costs and options across multiple suppliers. Our network of over 700 suppliers is also equipped to meet high volume pallet needs and geographic regions across the nation.

III. Specialty and Purpose-Specific Pallets

Other pallet types include specialty and purpose-specific pallets. These types of pallets typically are designed with specific use cases in mind.

Export Pallets

Export pallets must be ISPM-15 compliant, which means they must be constructed of heat-treated wood to be used in most countries. Export pallets also may be constructed of plastic, metal, or paper. Export pallets are a popular type of pallet that is lightweight and well-suited for international shipping.

Industry-Specific Pallets

There are several common varieties of industry-specific pallet types, as well. Food-grade pallets are made of virgin plastic or HT wood and must be FDA approved and NSF certified. Pharmaceutical pallets must be cleanroom compatible and serialized for traceability. Chemical pallets are constructed of chemical resistant plastic or treated steel to reduce spills. Pallets made specifically for cold storage are made of plastic or aluminum for resistance to moisture and cold temps. Finally, automotive pallets are heavy-duty pallets that are available in custom sizes, with the most common size being 48” by 45”.

Key Takeaways: Types of Pallets

- Different pallet construction types are used based on the type and weight of the freight being transported or stored.

- Stringer pallets: for standard shipping, with lighter-weight products, for general warehousing, and when manual handling is likely.

- Single-face pallets: for one-way shipping and storage only, and costs 20 to 30 percent less than double-face pallets.

- Double-face pallets: best for long-term use, racking, and frequent handling.

- Pallet type requirements differ based on geographical region, industry, and whether the products are being exported.

- Partner with the experts at PalletTrader to reduce costs and make better long-term decisions on your pallet spend.

Now that you’ve gained an understanding of different pallet types, explore which types of pallets are right for your specific application.

Explore the PalletTrader inventory to find the pallets you need.

Schedule a consultation to speak with a PalletTrader expert about your specific needs.